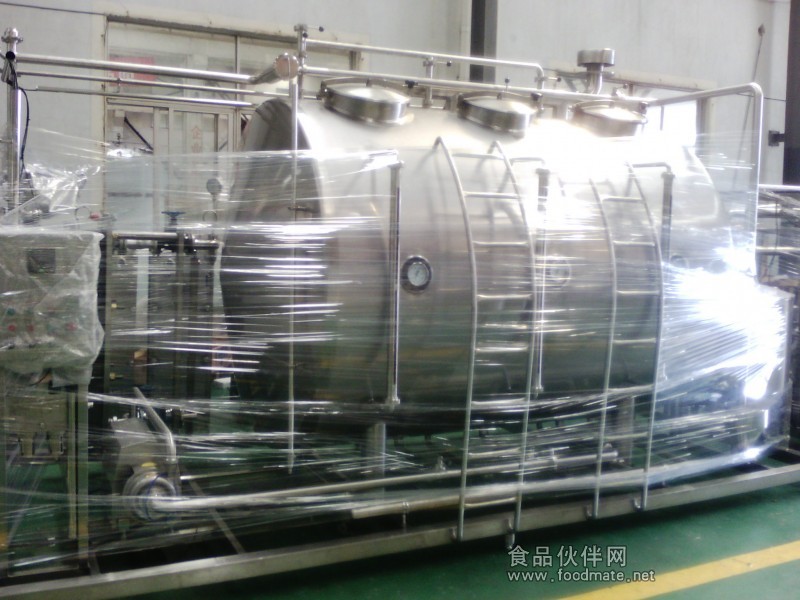

INTEGRAL TYPE CIP CLEANING SERIES

联体式CIP清洗系列

清洗液的加热用人工操作来实现;当清洗液的浓度达不到清洗浓度时,向酸液罐和碱液罐中添加浓酸和浓碱,也是人工来实现的;清洗时CIP液的输送也是通过人工操作相应的管路阀门进行的;罐内缺水时进行人工补水。

优点:就是设备资金的投入不大,对操作工人的专业知识要求不高,只要作适当的培训就可以进行生产。

缺点:自动化程度低,长远来看对人力的投入大;对清洗液的温度控制不精准;浓酸和浓碱的人工加入导致生产的安全系数的降低;生产效率低。

由于投资的成本不高,应是国内小型乳品和饮料等投资不是很大的工厂的。

Operators start heating of cleaning liquids. When concentration of cleaning liquid is not up to the concentration of cleaning, operator will add thick acid liquids or thick alkali liquids to acid tanks or alkali tanks. During cleaning, CIP liquids are fed through pipes and valves by operators. Operators shall add water into tanks when they are in shortage of water.

Advantages: medium capital investment on equipments and medium requirements on operators. After proper training, operator will be able to operate.

Disadvantages: little automatized. In a long run, investment on humans’labor is high. Control on temperature of cleaning liquid is not precise. Manual adding of thick acid an thick alkali degrades safety in production, and producting efficiency is low. For medium capital investment, it is a good choice for small manufacturers enterprises of dairy products an beverages.

技术参数 Technical Parameter

| 型号Model | SCIP-0.5 | SCIP-0.8 | SCIP-1 |

| 酸罐 Acid pot | 500L | 1000L | 1500L |

| 碱罐 Alkali pot | 500L | 1000L | 1500L |

| 水罐 Water pot | 500L | 1000L | 1500L |

| 泵流量 Pump flow | 10m3/h | 15m3/h | 20m3/h |

| 泵扬程 Pump lift | 36m | 36m | 36m |

| 泵功率 Pump motor | 2.2kw | 4kw | 5.5kw |

| 加热板片 Heating plate | 6m2 | 8m2 | 10m2 |

| 外形尺寸 Size | 2900*1000*1700mm | 3000*1200*1850mm | 3200*1400*2000mm |

| 设备重量 Weight | 350kg | 420kg | 480kg |